Product Introduction

Product Introduction

Low Temperature

Endurance of low temperature from 50℃ to 50℃.

All Transparent Explosion-proof Glass

15,30 and 50 models have transparent explosion-proof glass flap structure, which can clearly check the situation inside the equipment.

Fully Automatic and Manual

Fully Automatic and Manual

With the automatic extraction process,the program can set the drum rotation speed,time and cycle times,and can be switched to manual control.

Adjust

Adjust

Dehydration speed and time can be set.

Data Display

Data Display

Temperature display,vacuum pressure display.

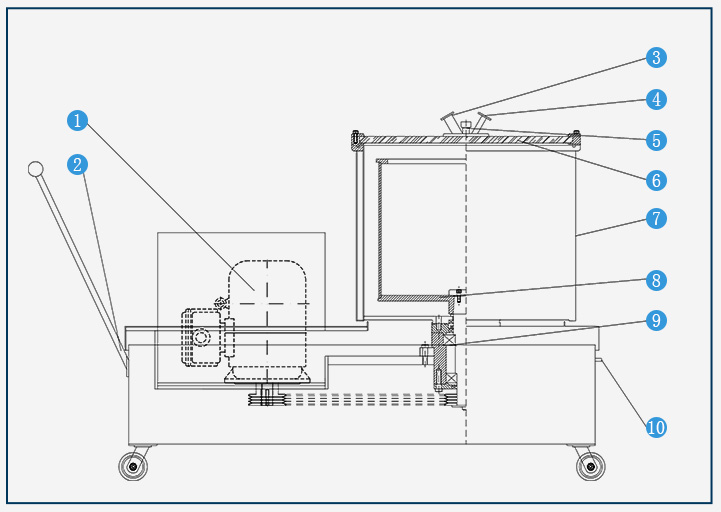

Leakage Indication Port

There is a leakage indication port at the bottom, if there is leakage,it can be found in time.

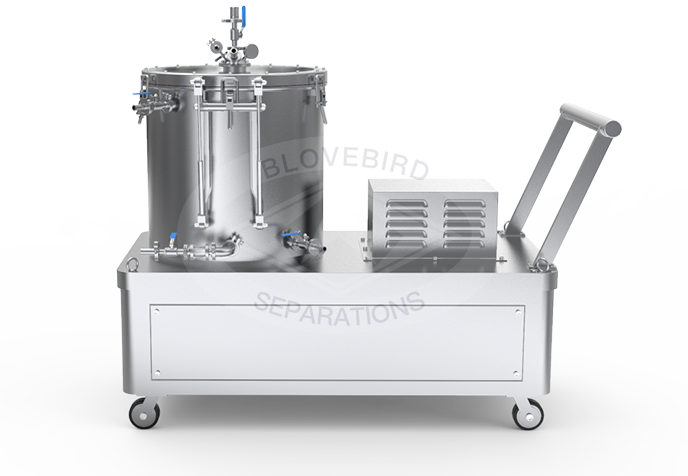

Single Person Operation

Zipper type filter bag can be loaded and unloaded quickly,designed for single person operation.

| Model |

Drum Diameter (mm) |

Speed (r/min) |

Separation Factor |

Feeding (kg) |

Cooling Volume (L) |

Power of Motor (kw) |

Weight (kg) |

Dimension (mm) |

| EEC15 | 300 | 2000 | 671 | 7 | 8 | 1.5 | 330 | 1100x600x1300 |

| EEC30 | 450 | 1500 | 566 | 14 | 19 | 4 | 520 | 1600x800x1400 |

| EEC50 | 600 | 1250 | 524 | 23 | 36 | 5.5 | 850 | 1800x1060x1450 |

| EEC100 | 800 | 1120 | 561 | 45 | 45 | 7.5 | 1350 | 1800x1200x1500 |

| EEC150 | 1000 | 1000 | 559 | 69 | 65 | 11 | 2000 | 1900x1550x1700 |

| EEC200 | 1250 | 900 | 566 | 91 | 100 | 15 | 2600 | 2300x1750x1950 |

30 Year Brand

Contact Us