Product Introduction

Product Introduction

High Efficiency

High Efficiency

The long-time working, spiral discharge with a large production capacity

Easy Operation

Easy Operation

The compact structure, convenient operation and repairment.

Wide Application Range

Wide Application Range

The wide application range with the machine,can be widely used in chemical, petroleum, food, pharmaceutical, environmental protection and other occasions that require solid-liquid separation;

Great Adaptability

Great Adaptability

Great adaptability to materials, the solid phase particle size range that can be separated is wide (0.005-2mm), and it can also be separated formally when the solid phase particle size is uneven.

Usages and Performance

Usages and Performance

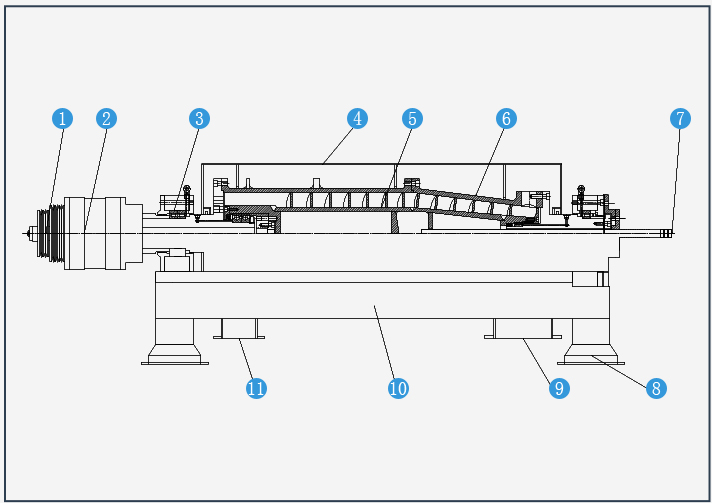

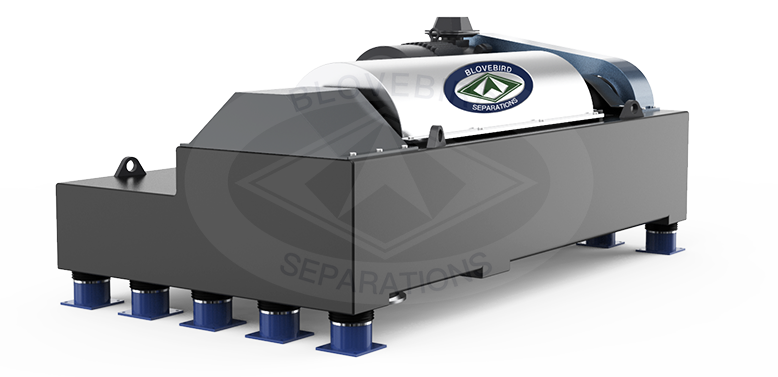

LW horizontal spiral discharge centrifuge is a sedimentation centrifuge with continuous working, and spiral discharging. It is mainly suitable for the solid-liquid separation, particle size classification, liquid phase clarification and sludge dewatering of various types of suspensions in various industrial sectors

Material Selection

Material Selection

The material of the part of the centrifuge contacting the mixture processed can be selected from austenitic stainless steel (321, 316L, etc.), Hastelloy, titanium alloy and other corrosion-resistant materials according to the requirements of client.

| Model |

Drum Diameter (mm) |

Aspect Ratio |

Speed (r/min) |

Separation Factor |

Processing Capacity (m3/H) |

Power of Motor (kw) |

Weight (kg) |

Dimension (mm) |

| LW220x800 | 220 | 4 | 4800 | 2840 | 0.5-2 | 11 | 1000 | 2260x740x780 |

| LW350X1400 | 350 | 4 | 4000 | 3100 | 3.0-12 | 22 | 2020 | 3550X1010X1030 |

| LW450X1800 | 450 | 4 | 3200 | 2577 | 6.0-20 | 30 | 3500 | 4120X1100X1250 |

| LW530X2120 | 530 | 4 | 2800 | 2327 | 12.0-30 | 55 | 4200 | 4730X1250X1460 |

| LW630X2300 | 630 | 3.65 | 2500 | 2205 | 25-35 | 75 | 8000 | 5110X1450X1750 |

30 Year Brand

Contact Us