Product Introduction

Product Introduction

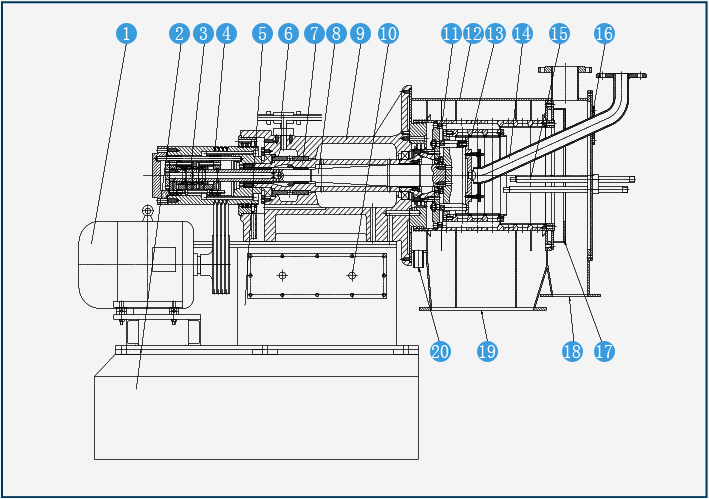

HR pusher centrifuge is a type of filtering centrifuge characterized by continuous feeding and intermittent discharging.It has the characteristics of completing feeding, separation, filter cake washing, spinning and unloading processes at full speed.

The main motor drives the inner and outer drums of the suit to rotate at full speed. The materials are continuously introduced by the feed pipe and evenly distributed on the inner wall of the inner drum. Under

the action of centrifugal force, the liquid phase passes through the filter and the drum wall. The hole is discharged and discharged out of the machine through the discharge pipe, and the solid phase is trapped

in the inner drum to form an annular filter cake layer. While the inner and outer drums rotate at the same speed, under the push of the piston, the inner drum continuously reciprocates axially, so the pusher disc

pushes the filter cake layer of the inner drum to move outwards intermittently and continuously to discharge the inner drum and enter the outer drum. drum. Thereby further separating and forming an annular filter

cake layer, the outer end surface of the inner drum pushes the outer drum filter cake layer to move out of the outer drum intermittently and continuously, and is discharged out of the machine through the scraper groove.

High Efficiency

High Efficiency

Continuous operation, large production capacity, stable performance.

High Separation Factor

High Separation Factor

The machine has a high volume of separation factor., the material can be fully dehydrated in the primary and secondary drum, and the filter cake contains less water than normal machines.

Effective Washing

Effective Washing

When the purity of the solid product is demanded, it can be effectively washed, and the washing liquid and mother liquor can be discharged separately.

Low Consumption

Low Consumption

Low power consumption.

Purpose

Purpose

The HR series centrifuge is a horizontal two-stage piston pusher, which is suitable for the separation of crystalline or fibrous suspensions containing medium particles with a concentration greater than 30% (the average crystal particle size is greater than 0.1mm) and the viscosity is small. It can be widely used in industries of chemical, salt, food, light sectors,etc.

Characteristic

Characteristic

HR series centrifuge has the traditional advantages of automatic continuous operation, continuous discharging of separated of materials, high production capacity, small crystal breakage, and washable filter cake. It also has high filter residue production capacity, high solid recovery rate, low filter residue moisture content, and no Peak conformance, fast drying, low energy consumption and other characteristics. And the parts of the machine in contact with materials are made of stainless steel, so it has good corrosion resistance.

Examples of Applied Materials

Production of sodium chloride, sodium sulfate, urea, PVC, boric acid, potassium chloride, potassium carbonate, potassium phosphate, ammonium bicarbonate, adipic acid, ammonium nitrate, etc.

| Model | HR400 | HR500 | HR630 | HR800 | HR1000 |

| Drum Diameter (mm) | 337/400 | 438/500 | 560/630 | 720/800 | 920/800 |

| Length of Filtering (mm) | 145/155 | 180/180 | 240/240 | 240/320 | 240/320 |

| Speed(r/min) | 1500-2200 | 1200-2000 | 1000-1800 | 800-1600 | 650-1250 |

| Separation Factor | 503-1083 | 402-1118 | 352-1140 | 286-1145 | 236-875 |

| Length of Stroke (mm) | 40 | 50 | 50 | 50 | 50 |

| Frequrncy of Stroke (Times/min) | 30-80 | 30-80 | 30-80 | 30-80 | 20-70 |

| Power of Motor (kw) | 7.5-15 | 30-55 | 37-55 | 55-75 | 75-90 |

| Oil Pump motor Power (kw) | 4/5.5 | 22 | 30 | 37 | 45 |

| Production Capacity (t/h) | 1-8 | 5-15 | 8-25 | 15-40 | 18-50 |

| Weight(kg) | 2480 | 3100 | 4100 | 7000 | 12000 |

| Dimension(mm) | 2460x1290x1030 | 2750x1480x1490 | 3690x1600x1265 | 3700x1800x1450 | 4200x1900x1900 |

30 Year Brand

Contact Us