Product Introduction

Product Introduction

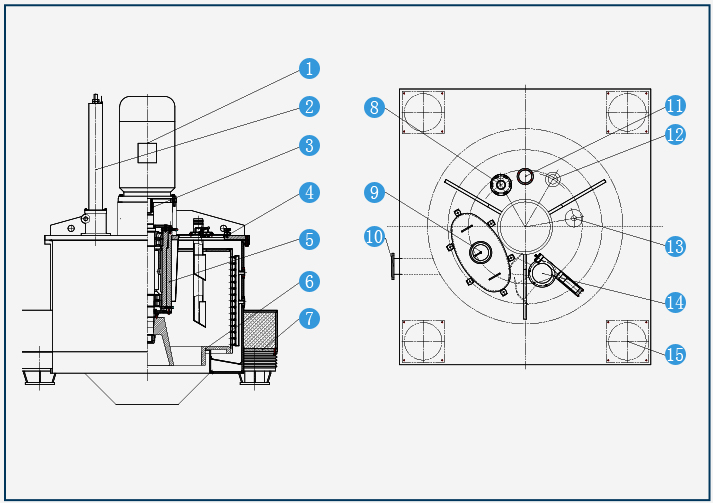

The top-suspended mechanical scraper unloading automatic centrifuge uses the centrifugal force field to separate solids and liquids. Through the radial and axial movement of the scraper, the material is scraped from the drum wall to complete the unloading process. The machine is equipped with water washing and air. Washing device, so the material is fully washed and the product quality is improved.

This sugar centrifuge can be used for the separation of methyl sugar (granulated sugar) and glucose paste, and is one of the key equipment in the sugar industry.

This machine can also be used to separate materials with finer solid crystal grains, greater viscosity, better fluidity, tighter texture, and difficult to discharge by gravity. Generally, the solid-liquid ratio (weight ratio) of the suspension is 45-60%.

The motor starts at low speed. When the feeding speed is reached, the feeding valve automatically opens to start feeding. The material is distributed on the inner surface of the drum through the cloth pan on the main shaft. With the help of the centrifugal force field, a cylindrical material layer is formed inside the drum. , The filtrate is discharged out of the drum through the screen and the small holes on the drum, and the filter cake is accumulated on the surface of the screen. The material layer detector starts to work while the material is being fed, and the thickness of the material layer gradually increases to the setting When the thickness of the material layer is greater than the thickness, the material layer detector sends a control signal, closes the feed valve, and the motor continues to increase the speed. In the process of increasing the speed, the washing valve is opened according to the requirements of the separation process, and the fully cylindrical washing of the cake layer after preliminary deliquoring is carried out. After the centrifuge is fully dewatered and the filter cake is dried to meet the separation requirements, it will enter the deceleration stage. At this time, the motor is in the generator state, and the mechanical energy is converted into electrical energy through the electrical system and sent back to the grid. When the speed drops to the unloading speed, the centrifugal centering device starts to work, the closed cover at the bottom opens, and the scraper cuts into the filter cake layer and moves axially with the action of the cylinder until the filter cake on the drum wall is All are scraped off, and the filter cake is discharged through the discharge port at the bottom of the drum along the guide of the scraper. After the discharge is completed, the closing cover is closed and the centering device is reset, and the transfer speed starts to increase from the discharge speed, and enters the next cycle.

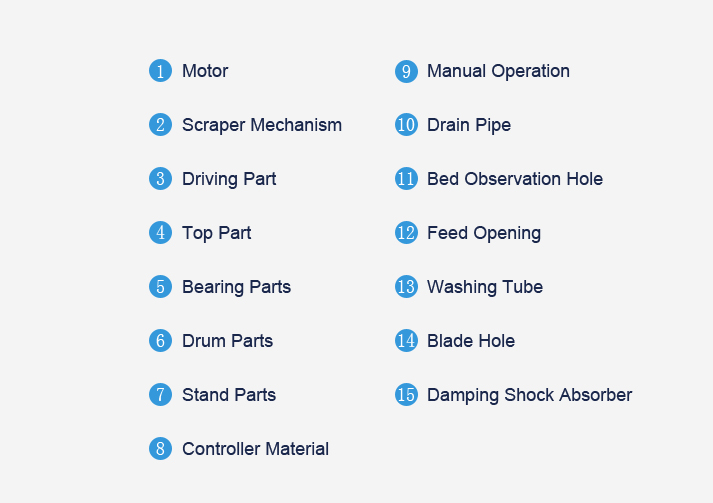

Flat Plate Structure

Flat Plate Structure

The Shell and The Frame

The Shell and The Frame

The Bearing Seat

The Bearing Seat

The Motor and Spindle

The Motor and Spindle

Hydraulic Brake Components

Hydraulic Brake Components

Gas-assisted Scraper and Gas-recoiler

Gas-assisted Scraper and Gas-recoiler

| Model |

Drum Diameter (mm) |

Speed (r/min) |

Separation Factor |

Drum Volume (L) |

Loading Limit (kg) |

Power of Motor (kw) |

Weight (kg) |

Dimension (mm) |

| PAUT1250A | 1250 | 970 | 658 | 350 | 520 | 22 | 5000 | 2100X2000X2200 |

| PAUT1250B | 1250 | 970 | 658 | 450 | 650 | 30 | 5800 | 2100X2000X2600 |

| PAUT1500 | 1500 | 850 | 606 | 580 | 720 | 37 | 8500 | 2500X2500X2600 |

| PAUT1600 | 1600 | 750 | 504 | 900 | 1200 | 45 | 12000 | 2750X2600X2800 |

30 Year Brand

Contact Us