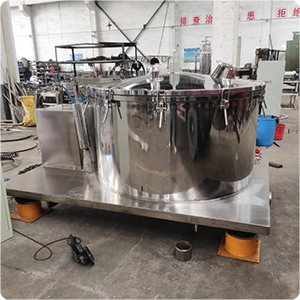

Introduction of Typical cases of Plate Type Centrifuge PB1000

Separation Material: carboxymethyl cellulose

Process Description:

First, carboxymethylcellulose is transferred from the system to the centrifuge. Under the action of the centrifugal force field generated by high-speed rotation, it is filtered through the filter medium, then dehydrated, and the carboxymethyl cellulose in the filter bag is collected.

Technical Features:

1. The motor adopts frequency conversion speed regulation, and the feeding, washing and separation speed of the centrifuge can be adjusted randomly.

2. The centrifuge adopts energy consumption braking mode of braking unit and braking resistance, with reliable braking performance.

3. Large flap structure is adopted. Each centrifuge is equipped with a spring cover opening system and 5 quick moving locks. Uncovering is portable, flexible, safe and reliable. Close the cover is convenient and quick, good sealing.

4. Feeding pipe is adopted to ensure uniform cloth and smooth operation of the machine.

Drum diameter: 1000mm Drum speed: 1000r/min