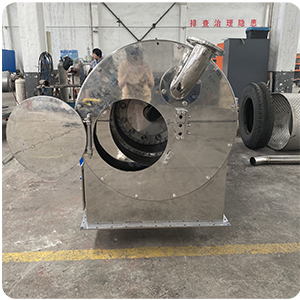

Introduction of Typical Cases HR series two-stage pusher centrifuge HR630

Separation material: Salt material

Process Description: The suspension continuously enters the conical distribution hopper installed on the pusher plate through the feeding pipe. The filter holes are thrown out of the drum, and the solid phase is trapped on the screen to form a cylindrical filter cake layer. The first-stage drum is controlled by the hydraulic system to continuously reciprocate. When the first-stage drum moves forward, the filter The cake layer is pushed forward for a certain distance, and after the first-stage drum moves backward, a new filter cake layer is formed on the vacated screen. Due to the non-stop reciprocating motion of the first-stage drum, the filter cake layer continues to rotate along the The drum wall moves axially forward and is finally pushed out of the drum. It is discharged out of the machine through the slag outlet of the casing, while the liquid phase is collected in the casing and discharged through the liquid discharge port of the casing.

Technical Features:

1. Continuous operation, large production capacity, stable operation

2. The separation factor is high, the material can be fully dehydrated in the primary and secondary drum, and the content of the filter cake is low.

3. When the purity of the solid product is required, it can be effectively washed, and the washing liquid and mother liquor can be disharged separately.

4. Low power consumption.

Drum diameter: 560/630mm Drum speed: 1000-1800rpm